Anti-corrosion and anti-chemical equipment lining (protection)

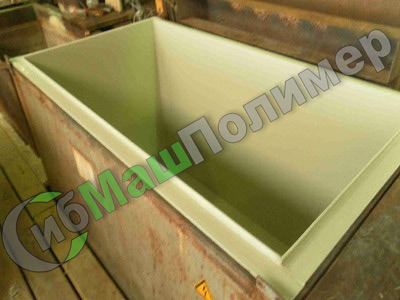

We perform lining with thermoforms (PP, PE, PVDF, ECTFE) on inner surfaces of baths, vessels, reactors, metal technological equipment, stainless steel and reinforced concrete affected by corrosive environment.

Thermoforms lining enables achieving the following goals, protecting equipment and pipelines used in corrosive environment:

- Efficient long-term protection of the operated equipment from corrosive working environments (acids, alkali, etc.)

- High product purity

- Significantly longer service life than for similar devices made from special steels or protected with other polymer materials

- Protecting various surfaces from product adhering (anti-adhesion protection

- On-site repair covering in the location where a device is installed.

There are two methods of thermoplastic lining:

-"Free insert" fixed on the frame of a bath, vessel or other protected equipment

- Sticking using matted thermoforms (PP, PVDF, ECTFE) that are stuck to a metal base with special sticking materials. Then thermoform edges are welded for additional leak-tightness.

Depending on the operating conditions, our specialists will find a reliable method and the most suitable thermoplastic – polypropylene (PP), polyethylene (PE), fluoroplastic (PVDF, ECTFE).

Our experts have vast experience in lining new equipment and reconstructing old (failed to function) equipment:

- Lining vessels for acids

- Lining reservoirs for corrosive liquids

- Lining plating baths

- Lining vessels for drinking water

- Lining chemical reactors

Lining (protection) of technological equipment from adhesion, friction and wear-out

Lining technological equipment protects it from wear and tear and eliminates the effects of adhesion and freezing-on of process materials.

Lining technological equipment from adhesion and wear-out is performed with ultrahigh molecular weight polyethylene (PE 500, PE 1000, Matrox®)

Lining with ultrahigh molecular weight materials is an efficient method of increasing economic return from the operated equipment: bankers, trays, hoppers, skips of largedump tracks, etc.

Lining (coating) with ultrahigh molecular weight thermoforms helps achieve the following objectives for protecting equipment working with such materials as coal, ore, clay, gypsum, grain, asphalt:

- Eliminate / considerably decrease material adhesion

- Eliminate tension and flow problems

- Eliminate material blocking in bankers, trays, etc.

- Increase equipment durability

- Extend equipment service life

- Protecting the core of a bunker, tray, skip, etc., from early wear.

Our specialists carry out works on:

- Lining silos, bankers

- Lining wagons for loose materials

- Lining dumptracks skips

- Lining trays

- Lining excavator buckets, bulldozer blades.