Preparation equipment

“SibMashPolymer” Ltd. designs, manufactures and supplies equipment for mining-and-processing, chemical, metallurgical and other industry sectors.

Preparation equipment is manufactured in line with specific requests of our Customers.

We use high-quality raw materials from the leading producers in Russia and Europe to manufacture preparation equipment:

- Polypropylene (PP-H, PP-R, PP-C, PPs, PPs-el)

- Polyethylene (PE 100, PE 100 RC, PE-el)

- Polyvinylchloride (PVC-U, PVC-MZ, PVC-C)

- Fluoroplastic (PVDF and ECTFE)

- Corrosion-resistant steels

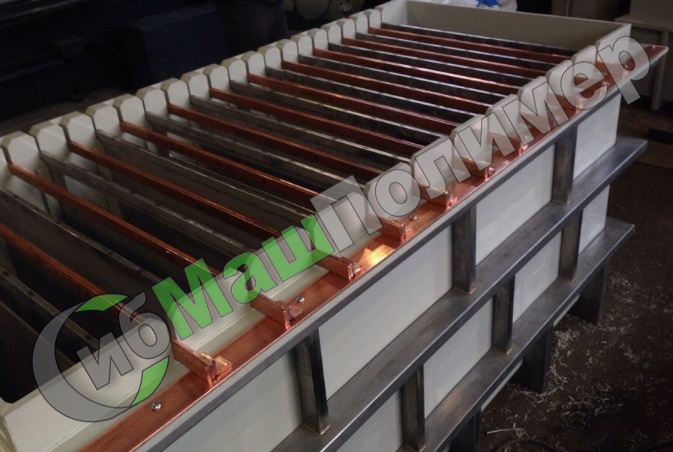

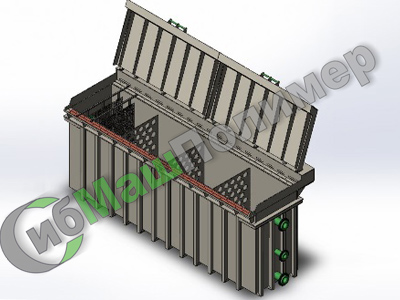

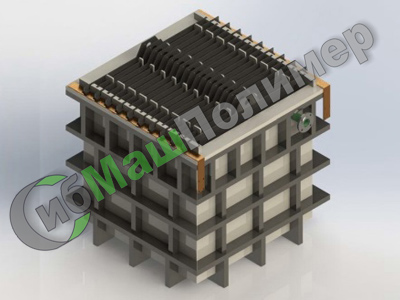

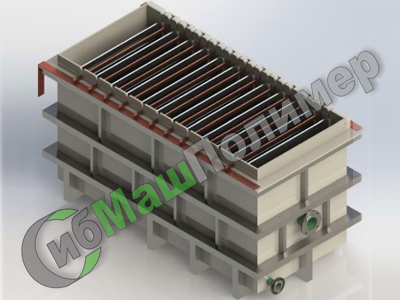

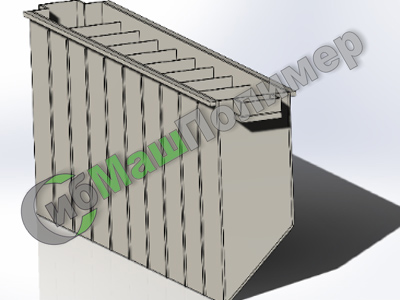

Electrolysis baths

Electrolysis baths are used for electrolysis, electrochemical and chemical treatment of precious and non-ferrous metals: copper, zinc, manganese, lead, etc., electrolysis.

Electrolysis baths are designed in estimating-analytical, CAD programs: design engineering, selecting material, its configuration, thickness, etc.

Completeness of electrolysis baths is determined together with the Customer drafting a technical-and-commercial proposal.

Possible options for manufacturing electrolysis baths:

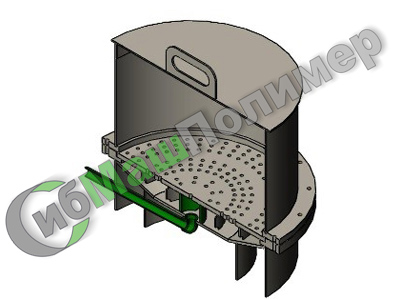

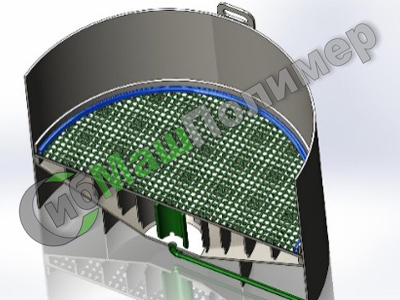

Acid treatment columns

Acid treatment columns (sorption columns) are used to extract (lixiviating) gold and silver from ore products, based on coal-sorption production technology.

Columns are designed in estimating-analytical, CAD programs on dimensions (drawings, sketches, technical specifications) given by the Customer.

Columns designs and completeness are determined together with the Customer drafting a technical-and-commercial proposal.

Possible options for column manufacturing:

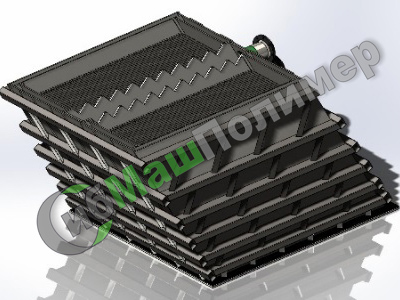

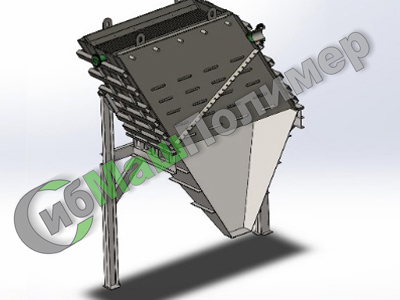

Nutsche-filters

Nutsche-filters are aimed to filer solutions at decreased pressure.

Nutsche-filters are made from polypropylene based on dimensions (drawings, sketches, technical specifications) given by the Customer.

Nutsche-filters are stocked with: grid; ring seal; net; cover if necessary.

Possible options for Nutsche-filters manufacturing:

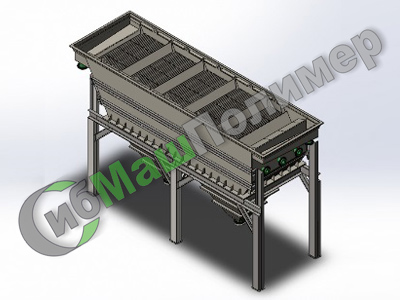

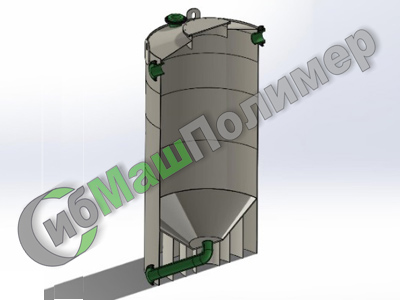

Settler-thickeners

Settler-thickeners are manufactured based on the dimensions (drawings, sketches, technical specifications) given by the Customer..

Design and completeness of settler-thickeners are determined together with the Customer drafting a technical-and-commercial proposal.

Possible options for manufacturing settler-thickeners:

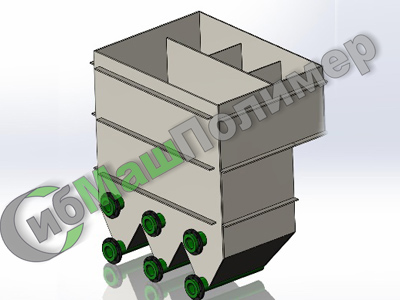

Centriclones, catchalls, deslimers

Centriclones, catchalls, deslimers are based on the dimensions (drawings, sketches, technical specifications) given by the Customer..Their design and completeness are determined together with the Customer drafting a technical-and-commercial proposal.

Our equipment fully meets the technical requirements set by the Customer.