Galvanic Equipment

“SibMashPolymer” Ltd. designs, manufactures and supplies equipment for various galvanic electroplating industries: machine-building, chemical, metallurgical and other fields.

We produce new equipment as well as reconstruct the existing one that came out of action due to chemical and corrosive wear.

Every piece of plating equipment is manufactured in line with specific requests of our Customers.

Our company is able to manufacture galvanic equipment of different complexity for any electroplated coating.

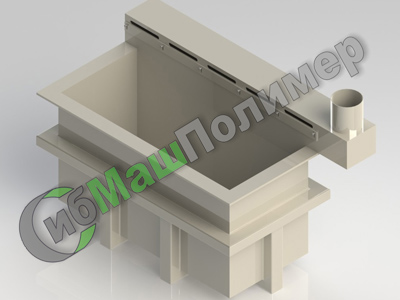

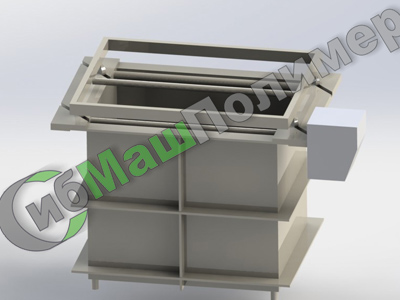

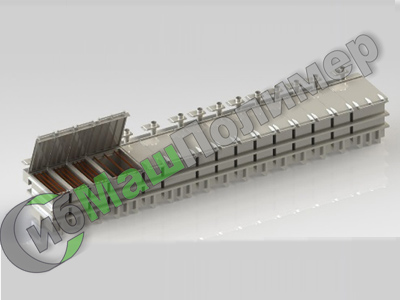

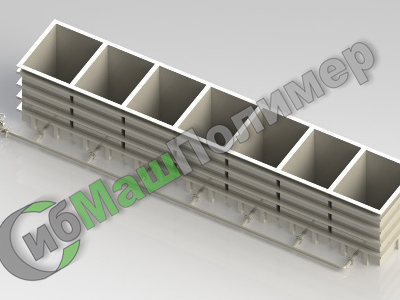

Plating baths are the main equipment used for electroplated coating.

We use quality raw materials from the leading producers in Russia and Europe to manufacture plating baths::

- Polypropylene (PP-H, PP-R, PP-C, PPs, PPs-el)

- Polyethylene (PE 100, PE 100 RC, PE-el)

- Polyvinylchloride (PVC-U, PVC-MZ, PVC-C)

- Fluoroplastic (PVDF и ECTFE)

- Corrosion-resistant steels

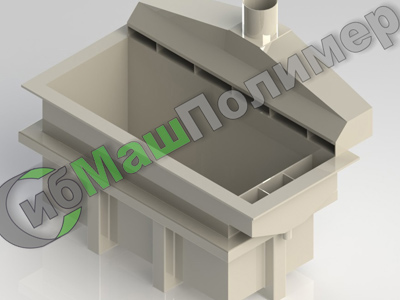

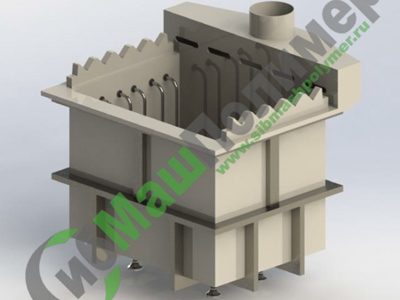

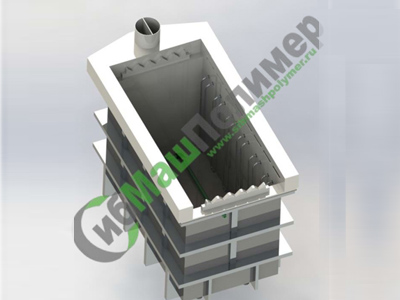

Plating baths from polypropylene (PP)

Polypropylene (PP) –is the most popular polymer material, it is resistant to most acids and alkali, and is meant for up to +100°С solution temperature (short-term - 110°С). Due to its excellent chemical and thermal resistance, Polypropylene is widely used for both manufacturing bath tubs and lining inner bath surfaces.

Design of polypropylene plating baths provides for installing vertical and horizontal reinforcing plates; the wall thickness of plate polypropylene is determined depending on the qualities (pressure, density, temperature) of a solution to be used at work. Large-size baths are manufactured in a metal framing.

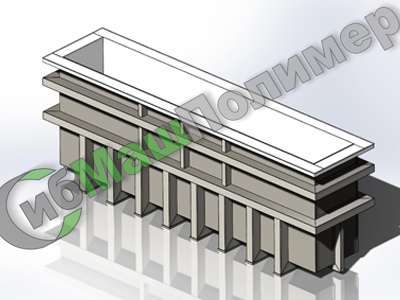

Plating bathes from polyvinylchloride (PVC)

Plating bathes from polyvinylchloride (PVC) are most frequently used for clarification and passivation (nitric acid solutions, chromium electrolytes, etc.)

Polyvinylchloride is most often used for inner lining; however, it can also be used in manufacturing bath tubs and constructions.

Polypropylene plating baths lined with fluoriplastic

Plating bath tub is made of polypropylene (PP).Inner surfaces of polypropylene baths are lined with fluoroplastic: PVDF and ECTFE,the material is selected based on the parameters of a particular technological process – electrolyte composition, concentration of its components, operating temperature.

Fluoroplastic-lined baths are suitable for chromium plating, chrome passivation, electrolytic polishing, chrome anodic treatment, etc. Fluoroplastic is resistant in all corrosive environments and withstands up to 140 °С.

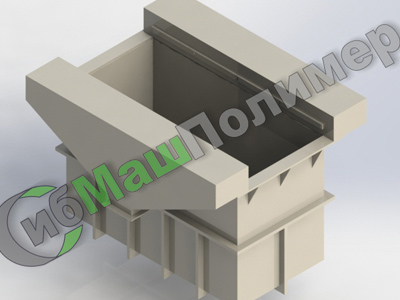

Metal plating baths

Plating bath is made from metal (stainless steel, plain carbon steel) without lining. The steel grade is selected based on galvanic technology. Bath steel-frames are mostly used for the galvanic process characterized with high temperature (≥110°С) and non-aggressive or mildly aggressive environment (phosphate treatment, oxidation, washing-up, drying, etc.).In all other galvanic processes the inner surface of bath steel-frame is protected (lined) with corrosion-resistant materials (thermoplastic, plastic compounds, etc.).

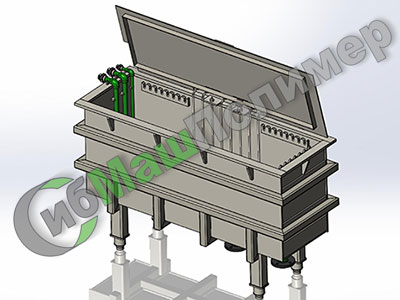

Steel plating baths lined with thermoplastic

Plating bath tubs are made of stainless steel orplain carbon steel, the inner surface of metal baths is lined with plate thermoplastic (polypropylene (PP), polyvinylchloride (PVC), polyvinyliden fluoride (PVDF), ethylene-chlorotrifluoroethylene (ECTFE)).

The bath lining material is selected based on technological specifics of a production process, electrolyte concentration and operational temperature.

Possible vessel options:

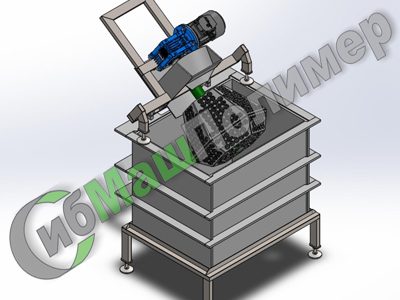

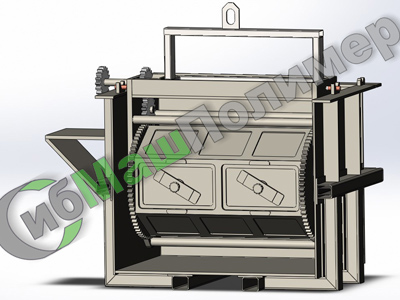

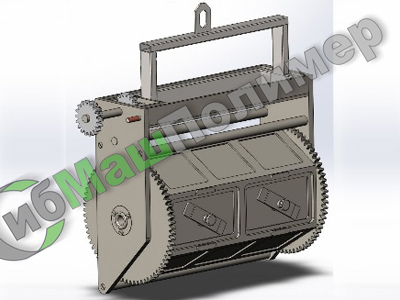

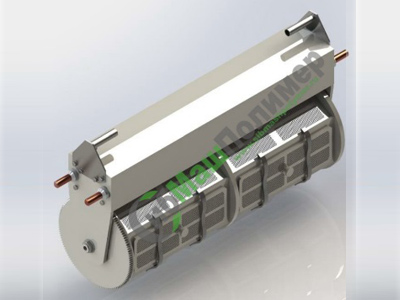

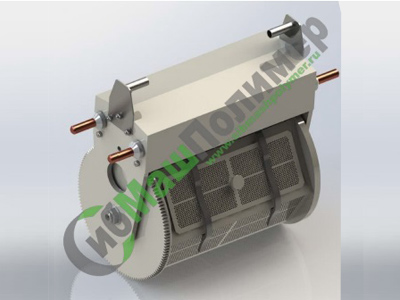

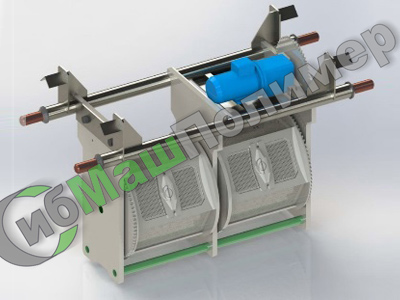

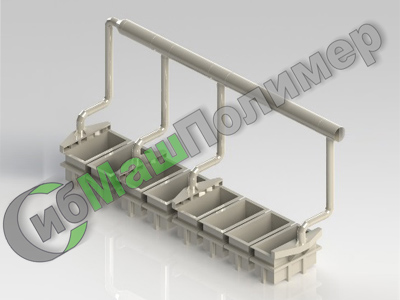

Plating barrels

Plating barrels are fully polypropylene-made, which guarantees a high degree of a barrel resistance to chemical impact of aggressive environments, corrosion and elevated temperatures. We can manufacture barrels for any load, of any dimensions and perforation diameter.

Possible options for plating barrels:

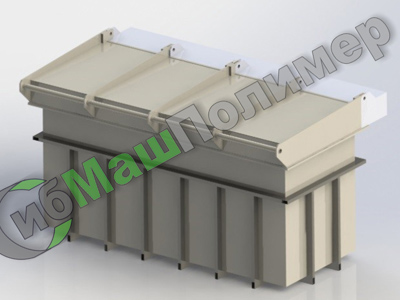

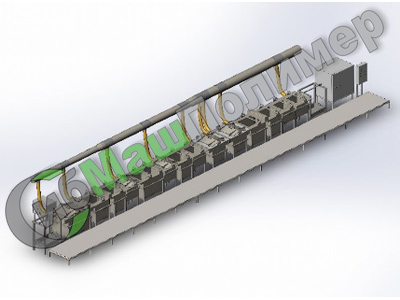

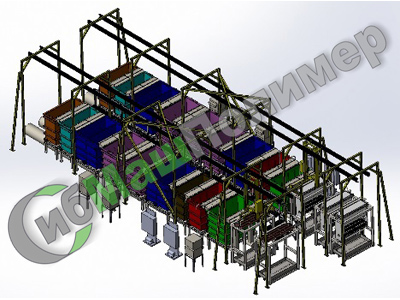

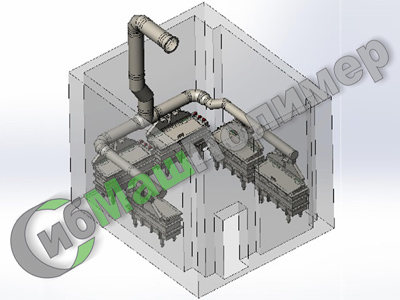

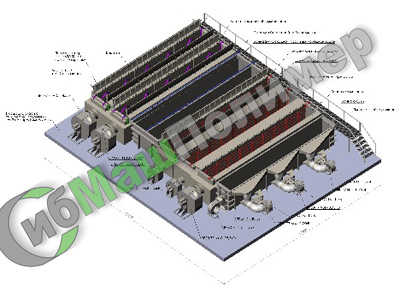

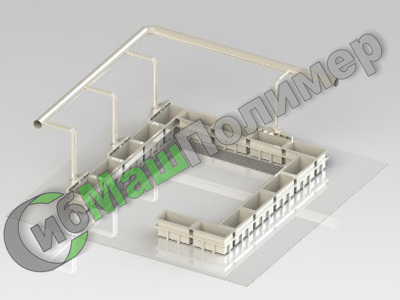

Galvanizing lines

Experts of “SibMashPolymer” Ltd. manufacture and assemble galvanizing lines for different types of plating: zinc coating, chrome finish, anodizing, cadmium-plating, etc. Galvanizing lines can be made to perform single or several types of coating (multi-process galvanizing lines).

Types of galvanizing lines:- Manual

- Mechanical

- Semi-automated

- Automated

Galvanizing lines made by “SibMashPolymer” fully comply with technical specifications requested by our Customers.